Electrical Contracting

Electrification Overview

Avitas Electric is leading integrated Electrification service provider with over several years of experience in providing expert solutions in the building, industrial, Infrastructure, Power & Energy and Life Sciences segments. It has built for itself, an enviable reputation for being a one-stop turnkey provider for all MEP needs, with a strong record of delivering several projects across India. Its potent blend of technical know-how, talented workforce, design expertise, exceptional project execution capabilities and global footprint makes it the most preferred choice for Electrification projects. Backed by a strong team of experienced employees, well-networked global supply chains and engineering excellence, the Company has leveraged the opportunity of being part of engineering marvels across geographies.

Integrated Electrification Services

The Company offers the following integrated Electrification services

- Design, detailed engineering, procurement, project management, installation, testing, commissioning, liaisoning, approvals of 33kV, 11kV and Low voltages power distribution external and internal.

- Design and execution of electrical contracting projects.

- Design and execution of Medium voltage system.

- Design and execution of low voltage systems.

Advantage Avitas Electric

Superior project delivery through intelligent engineering, modern execution practices and committed teams.

Avitas Electric has a proven track record of technical competence, professional management and commitment to customer satisfaction. The Company offers a wealth of experience in Electrical equipment manufacturing, Engineering, Procurement and Substation construction projects as well as Mechanical EPC projects.

Diversified work culture and working experience in Industry, Infrastructure, Energy & Power, Healthcare, Building, Institutional projects stand witness to Avitas Electric superior project delivery.

A Committed Engineering Company

Avitas Electric has been in the manufacturing & projects business for over several years and has delivered consistently, reinventing itself to meet evolving market requirements, despite market volatility. The Company has displayed unmatched competence in the execution of large and technically challenging projects.

Committed Teams

The Company consists of highly knowledgeable, experienced, customer-focused engineers and managers who honour Avitas endeavor to deliver world-class customer experience.

Intelligent Engineering Practices

The Company's engineers accord utmost

importance to system design,

equipment selection

and work

methods to arrive at recommendations for cost reduction, efficiency improvement, power

reduction

and reliability improvement.

The team uses a sophisticated 3D

modelling

software to produce coordinated and

clash-free

drawings.

Modern quantity take-off estimation tools such as EPLAN, etap are used for planning

&

design of

electrical jobs.

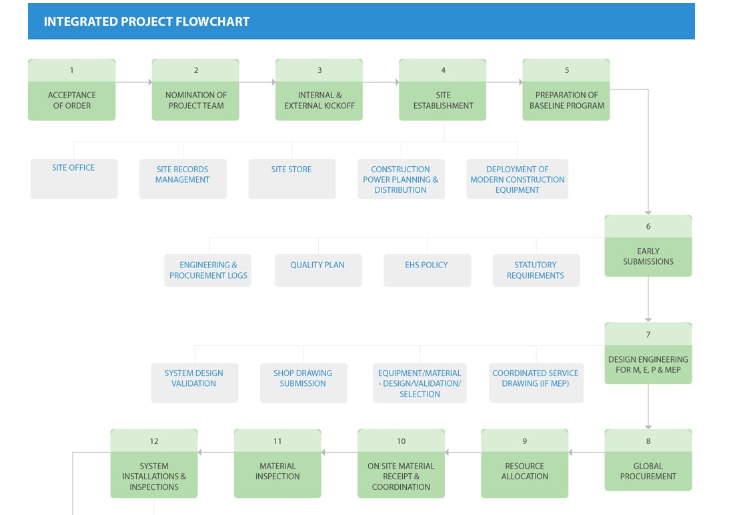

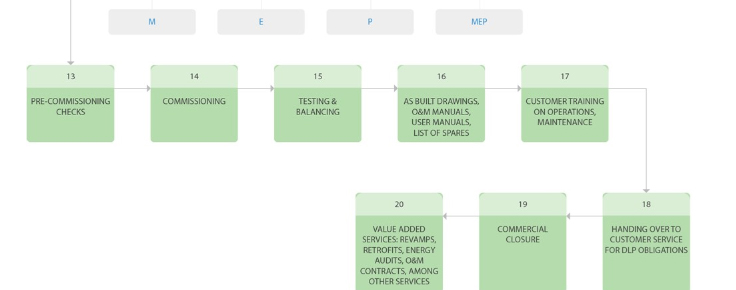

Modern Project Management Practices

The Company has identified multiple initiatives for stronger project management and procurement practices and plans to institutionalize modern site practices based on manufacturing principles to ensure a differentiated delivery experience. It will also IT-enable its business processes while judiciously investing in manufacturing & contracting with the objective of driving productivity and consistency in its deliverables.

Activities such as project start-up, site mobilization, work execution, project completion and project handover are performed in a thoroughly professional manner as per processes prescribed in the Avitas Electric Project Management Guide. Monthly site walkthroughs are carried out by the Delivery Head.

Modern Site Practices

Site facilities such as site office, site store, site records and construction power are planned and set up in a professional manner from the beginning of the job.

Engineers and business associates are inducted into their work profiles, safety practices, legal compliances and work standards in a systematic way during the initial stage.

Construction equipment is selected and indented as per prescribed standards during the site mobilization phase to ensure high productivity levels.

Pre-fabrication is actively encouraged to optimize quality levels.

Installation and commissioning checklists are used for assurance of work quality.

Customer-friendly Organization

In a world that is getting increasingly mechanical and impersonal, Avitas Electric customer-friendly culture offers a significant amount of meaningful human contact to foster mutually beneficial relationships. The dependability and trustworthiness of the human resources of the Company is an assured deliverable with every project on which a customer partners with Avitas Electric.

3C PROGRAMME

Comprehensive Contracting Capability

Avitas Electric's Comprehensive Contracting Capability Program - also known as the 3C Program - aims at constantly achieving higher customer satisfaction ratings across the entire spectrum of electro- mechanical projects, through the following:

- Achievement of all design and performance criteria

- On-time completion of projects

- Maintenance of the highest quality standards

- Integrate control of emergency lighting circuits

- Completion of projects within defined budgets

The goals of the 3C program are pursued at Avitas Electric through the continuous quest for excellence in every functional area, including project, site & subcontract management, engineering quality, processes & controls, construction practices, and skilling & training.

Project Management

Single-window point of interaction for all services and activities, aided by a project management guide, developed in-house.

Avitas Electric's Comprehensive Contracting Capability Program - also known as the 3C Program - aims at constantly achieving higher customer satisfaction ratings across the entire spectrum of electro- mechanical projects, through the following:

- Achievement of all design and performance criteria

- On-time completion of projects

- Maintenance of the highest quality standards

- Integrate control of emergency lighting circuits

- Completion of projects within defined budgets

The goals of the 3C program are pursued at Avitas Electric through the continuous quest for excellence in every functional area, including project, site & subcontract management, engineering quality, processes & controls, construction practices, and skilling & training.

Site Management

- Standardization of site facilities, including site stores, site office, and construction power

- Standardization of site records for document and version traceability.

- Site processes like variable quantity certification and site work instruction forms for smooth and accurate measurements and claims.

- Installation and commissioning checklists for communicating standards and monitoring construction quality.

Engineering Quality

Usage of EPLAN for multi-service coordination and interference detection. Continuous upskilling of engineering team on CAD standards, shop drawing quality and technical training.

Modern Construction Practices

Motivating subcontractors to adapt to modern construction tools.

Driving mechanization and prefabrication to reduce construction duration at site.

Skilling & Training

- Dedicated training organization located in Hyderabad.

- Portfolio of training to strike the best balance between technical, functional and behavioural aspects.

- Faculty comprising both in-house and industry experts.

The 3C programme implementation uses the well-tested route of inducting teams into initiatives, training them on the process using work instruction sheets, managing knowledge by sharing information on the online portal, strengthening the implementation via field guidance, and auditing levels of implementation and gathering feedback.

SAFETY POLICY

Avitas Electric management firmly believes that the safety of its employees and all stakeholders associated with the Company’s project sites and manufacturing facilities is of utmost importance. Safety is an essential and integral part of all the Company’s work activities which includes planning, design, procurement, fabrication, construction, installation and commissioning of facilities, products, manufacturing processes and services. Avitas Electric believes that incidents or accidents and risk to health are preventable through the active involvement of all stakeholders, thereby creating a safe and accident-free workplace.

Essential Safety Practices

To ensure safety while at work within Avitas Electric, the Company has identified from experience Essential Safety Practices (ESPs) that must be followed strictly and without exception in each of its operational verticals, with Manufacturing and Project Management being the two key fields most prone to accidents. The ESPs address inherent safety hazards in each of the verticals, thus increasing the levels of safety.